Commitment to Continuous Improvement

Wilmanco is committed to continuous improvement in product quality, production efficiency, and competitive pricing. We implement strict quality controls and invest in the most advanced CNC machines to provide our customers with the best precision RF products. With over 40 years of experience in RF design and manufacturing, Wilmanco is a trusted name across various industries for our high-quality integrated electronic assemblies and machined components.

Advanced Manufacturing Equipment

We use the industry’s finest CNC machines to facilitate a broad range of RF manufacturing needs. Currently, our machine shop operates the following advanced CNC machinery:

- HAAS VMC VF-5SS. With a 12,000 RPM spindle and a 50″ x 24″ x 25″ work envelope, this machine is ideal for high-speed machining projects.

- HAAS VMC VF-3SS. With comparable spindle speeds and a slightly smaller work area than the VF-5SS, the VF-3SS offers greater flexibility to support a wider range of project sizes.

- HAAS HMC ES5-4T. This horizontal mill features a 12,000 RPM spindle and a rotary table with limited 4th-axis capabilities, ideal for projects with more complex geometries.

- Fadal VMC 4020 and 2520. These CNC machines feature adjustable spindle speeds and varying work envelope sizes, allowing us to meet strict manufacturing requirements for efficiency, precision, and complexity.

Precision Measurement and Quality Assurance

RF product quality is paramount, so Wilmanco implements the most advanced measurement and quality assurance equipment:

- 3D printers. Our 3D printing capabilities enable us to create rapid prototypes and fixtures. We also can make design adjustments quicker, streamlining the entire design verification process.

- Brown & Sharpe CMM (with Renishaw PH20 head). This ultra-precise measuring device verifies that each product meets exact tolerance windows and allows us to track process capabilities at every stage.

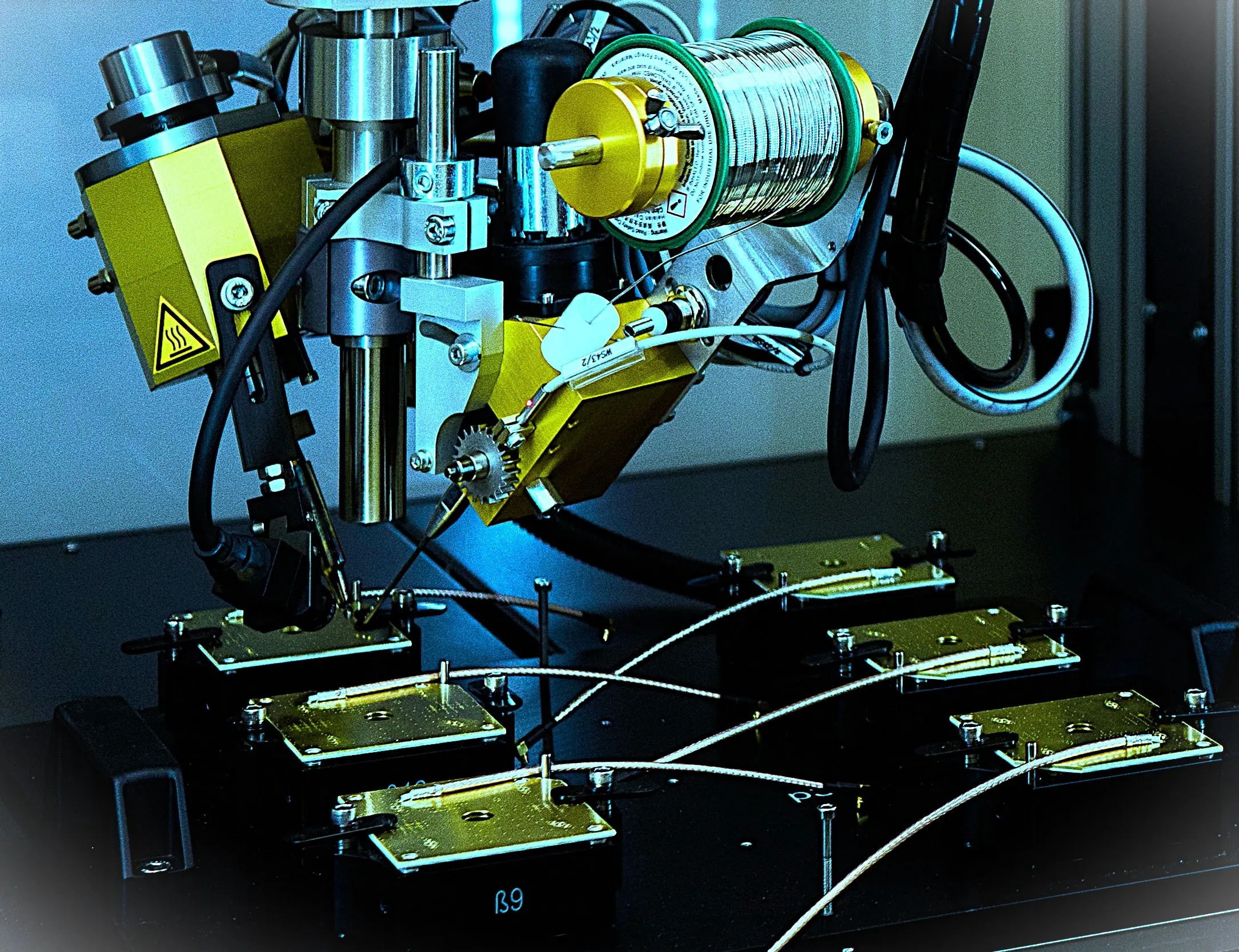

Comprehensive Production Capabilities

Our entire production floor is equipped to accommodate and maintain control over a wide range of manufacturing and assembly processes. Specific capabilities include:

- Pemserter 4 machines, which facilitate more efficient fastener insertion for sheet metal components.

- Custom automation equipment, such as automated solder and screwdriver machines, to optimize assembly speed and consistency.

- Testing facilities, including spectrum analyzers, network analyzers, and anechoic RF test chambers, to verify all Wilmanco products meet or exceed design specifications.

Rigorous Quality Control Measures

By adopting ISO 9001:2015 quality management standards, Wilmanco delivers the highest-quality products and services. Our robust quality control measures include:

- Process controls. We build trust with our customers through responsive communication and full transparency to deliver products on time and within budget.

- Material requirements planning (MRP). We customize our MRP process to each customer’s needs, ensuring the utmost quality and efficiency from material procurement to final delivery.

- Counterfeit component mitigation. By working only with vetted, approved suppliers and meticulously examining all parts, Wilmanco proactively protects our customers from counterfeit risks.

Partner With Wilmanco for Precision Manufacturing

At Wilmanco, we invest in the most advanced CNC machines and quality controls to ensure every product meets or exceeds your standards. From product design and prototyping to full production and final delivery, we prioritize quality, efficiency, and cost-effectiveness. To learn more about our contract manufacturing capabilities or other services, contact us today.